MRL - Pesticide Residue Management in Mango

(Mangifera indica L.)

Mango (Mangifera indica L.) is the most important fruit of India and is known as the “King of fruits.” India is the home of about 1,000 varieties and ranks first among the world’s mango-producing countries, accounting for about 50% of the world’s mango production. The fruit is cultivated in the largest area, i.e., 2.312 thousand ha, and the production is around 15.03 million tonnes, contributing 40.48% of the total world production of mango. The main mango-producing states in India are Uttar Pradesh (23.86%), Andhra Pradesh (22.14%), Karnataka (11.71%), Bihar (8.79%), Gujarat (6.00%), and Tamil Nadu (5.09%). India is also a prominent exporter of fresh mangoes to the world. India exports mangoes to over 40 countries worldwide. The country has exported 36,329.01 MT of fresh mangoes to the world for the worth of Rs. 317.10 crores during the year 2015-16. Major Export destinations are the United Arab Emirates, the United Kingdom, Saudi Arabia, Nepal, Kuwait, Bangladesh, and Bahrain, etc. India is also a major exporter of mango pulp in the world. The country has exported 1,28,866.01 MT of mango pulp worth Rs. 796.17 crores during the year 2015-16.

Mango crops are affected by a number of pests and diseases, the major insect pests of mango are fruit flies, mango hoppers, mealybugs, scales, shoot borers, stem borers, stone weevils, etc. The major diseases of mango are anthracnose, bacterial leaf blight, and powdery mildew, etc. For controlling these pests and diseases, a large number of pesticides are applied to the crop throughout the cropping season. Contact pesticides remain on the surface, whereas systemic pesticides are absorbed by the plant tissues. Repeated application of pesticides may lead to the build-up of residues, leading to residue levels in the harvested produce above the maximum residue limits. Pesticides from soil application, packaging materials, and pack houses may also contaminate mango fruits. Food safety is a major concern in countries worldwide, and it has taken center stage in the global food trade. The exported mango fruits should not exceed the maximum residue limits of the importing countries.

Maximum residue limits

Pesticides used on food crops may leave residues on these crops. Maximum Residue Limits (MRLs) are the upper legal levels of a concentration for pesticide residues in/on food or feed based on good agricultural practices and to ensure the lowest possible consumer exposure. They act as an indicator of the correct use of pesticides and ensure compliance with legal requirements for low residues on unprocessed food. MRLs are set at low levels to ensure that high-level consumers will not consume more than the acceptable daily intake (ADI) if they eat large quantities of every food type containing the residues at the MRL. Nationally established MRLs for pesticides are based on national conditions and practices. It is possible, therefore, for different countries to set different MRLs for the same pesticide/food commodity combination. It is also possible that a pesticide authorized in one country is not authorized for use in another. These factors can result in unintentional barriers to trade. While exporting mango, the MRLs set by the importing country must be adhered to.

Table 1. MRL, of pesticides on mango notified in different countries

Pesticide | EU (mg/kg) | UK (mg/kg) | MRL (mg/kg) | Australia (mg/kg) | Codex (mg/kg) | Japan (mg/kg) |

Acephate | 0.01 | 0.02 | 0.50 | 0.7 | 1.00 | |

Azoxystrobin | 0.70 | 0.20 | – | – | – | |

Bifenthrin | 0.30 | 0.30 | 0.20 | 0.10 | 0.30 | |

Buprofezin | 0.10 | – | – | – | 0.90 | |

Carbendazim | 0.50 | 0.10 | 2.0 | 0.05 | 5.00 | 2.00 |

Chlorpyrifos | 0.05 | 0.05 | 0.5 | – | – | 0.05 |

Cypermethrin | 0.05 | 0.05 | – | 0.70 | 0.03 | |

Deltamethrin | 0.05 | 0.05 | – | – | 0.50 | |

Dicofol | 0.02 | 0.02 | 5.0 | – | 0.07 | 3.00 |

Difenoconazole | 0.10 | – | – | – | 0.07 | |

Dimethoate | 0.02 | 0.02 | 2.0 | 1.00 | 1.00 | 1.00 |

Dinocap | 0.02 | – | – | – | – | |

Dithiocarbamates | 2.00 | – | 3.0 | 7.00 | 2.00 | 2.00 |

Ethefon | 0.05 | – | 0.02 | – | 2.00 | |

Ethion | 0.01 | 0.01 | 2.0 | – | – | 0.30 |

Fenvalerate | 1.50 | 0.02 | – | – | 1.00 | |

Hexaconazole | 0.01 | 0.02 | – | 0.20 | 0.07 | |

Imidacloprid | 0.20 | – | – | 0.20 | 1.00 | |

Lambda-cyhalothrin | 0.20 | 0.10 | – | – | – | |

Malathion | 0.02 | 0.01 | 4.0 | – | – | 8.00 |

Monocrotophos | 0.01 | – | 1.0 | – | – | – |

Oxydemeton-methyl | 0.01 | 0.02 | – | – | 0.02 | |

Phosphamidon | 0.01 | 0.01 | 0.2 | – | – | 0.20 |

Propiconazole | 0.05 | 0.05 | – | – | 0.05 | |

Pyraclostrobin | 0.05 | 0.05 | 0.10 | 0.30 | 0.05 | |

Spirotetramat | 0.30 | – | 0.30 | 0.30 | 0.30 | |

Tebuconazole | 0.10 | – | – | 0.05 | 0.10 | |

Trifloxystrobin | 0.01 | – | – | – | 0.70 | |

Thiamethoxam | 0.01 | 0.50 | 0.07 | 0.20 | 0.20 | |

Triadimefon | 0.05 | 0.10 | – | – | 0.05 | |

Triadimenol | 0.05 | 0.10 | – | – | 0.05 |

Pre-harvest interval (PHI)

PHI is the time gap between the last application and the harvest of the crop to ensure pesticide residue level to remain within the permissible level, i.e. the MRL. It is basically a withholding period to meet the MRL. PHI is crop and pesticide specific. If pesticides are applied on mango at the growth stage of the crop using the recommended dosage and the appropriate PHIs are allowed, the harvested produce will have residues within the specified MRL. PHI of pesticides on mango have been calculated based on the residue data generated from supervised field trials carried out at the experimental field of IIHR, Bengaluru as per GAP. The residue data thus generated and the European Union MRLs of pesticides on mango has been taken into account to calculate the PHI (Table 2).

Table 2 Pre-harvest intervals of pesticides on mango

Absolutely! Here is the data from the image converted into a chart table format:

Pesticide | Pest/Disease | Dosage Formulation | EU MRL (mg/kg) | Pre-harvest Interval (days) |

Azoxystrobin 23% SC | Anthracnose, Powdery mildew | 1.0 mL/L | 0.70 | 15 |

*Bifenthrin 10% EC | Hopper | 0.5 mL/L | 0.30 | 16 |

Buprofezin 25% SC | Hopper | 1.0 mL/L | 0.10 | 15 |

Carbendazim 50% WP | Anthracnose, Powdery mildew | 1.0 g/L | 0.50 | 60 |

*Cypermethrin 25% SC | Hopper | 1.0 mL/L | 0.05 | 30 |

*Difenoconazole 25% SC | Stem end rot | 0.5 mL/L | 0.10 | 21 |

Deltamethrin 2.8% EC | Hopper | 1.0 mL/L | 0.05 | 30 |

Dimethoate 30% EC | Mealy bug, Hopper | 1.5 g/L | 0.02 | 60 |

Dinocap 48% EC | Powdery mildew | 0.5 mL/L | 0.02 | 30 |

*Fenvalerate 20% EC | Hopper | 1.0 mL/L | 1.50 | 30 |

Hexaconazole 5% EC | Powdery mildew | 1.0 mL/L | 0.01 | 20 |

Imidacloprid 17.8% SL | Hopper, Scale | 0.4 mL/L | 0.20 | 60 |

Lambda-cyhalothrin 5% EC | Hopper | 1.0 mL/L | 0.20 | 15 |

Malathion 50% EC | Mealy scale, Hopper | 1.5 mL/L | 0.02 | 25 |

Oxydemeton-methyl 25% EC | Hopper | 1.0 mL/L | 0.01 | 65 |

Thiamethoxam 25% WG | Hopper, Thrips | 0.25 g/L | 0.01 | 48 |

Combination Formulations | ||||

Carbendazim 12% + Mancozeb 63% WP | Powdery mildew, Anthracnose, Blossom blight | 0.11% | 0.5+2.0 | 45 |

Beta cyfluthrin 9% + imidacloprid 21% | Powdery mildew | 0.025% | 0.02+0.2 | 45 |

Spirotetramat 12% + imidacloprid 12% | Hopper, Aphid | 0.075% | 0.3+0.2 | 30 |

Trifloxystrobin 25% + tebuconazole 50% | Powdery mildew and Anthracnose | 0.1% | 0.01+0.1 | 45 |

*Without CIBRC recommendation

Mango production and pesticide residues

Application of pesticides has become a necessity for increasing the mango production. Pesticides applied to crops dissipate due to various physical and chemical parameters, environmental parameters including growth dilution factors. Pesticides applied at the initial stages of fruit growth dissipates due to growth dilution effect. As mango fruits are slow growing in nature, application of pesticides towards maturity increases the chances of having residues above the MRL at harvest. The PHIs have been worked out by giving pesticide application at the growth stage of the mango crop (immature fruits). It is not applicable if pesticide application is given to mature mango fruits (fully grown). As a thumb rule NO pesticide application should be given to mango crop 1 month within harvest.

Residue analysis of pesticides on mango

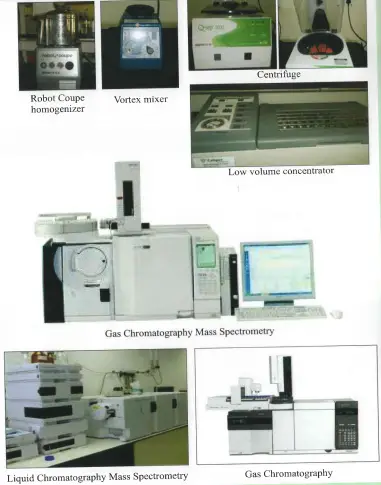

Pesticide residue analysis in mango is carried out in the Pesticide Residue Laboratory, ICAR-IIHR, Bangalore using the QuEChERS method in conjunction with liquid chromatography mass spectrometry (LC-MS/MS), gas chromatography mass spectrometry (GC-MS) and gas chromatography (GC).

QuEChERS Analytical Method

Cut 2 kg mango fruits into small pieces.

Homogenize in a high-volume Robot Coupe homogenizer.

⬇

Place 15 g sample in 50 mL polypropylene tube.

⬇

Add 15 mL of 1% acetic acid in HPLC grade acetonitrile.

⬇

Add 6 g anhydrous magnesium sulphate, 1.5 g of sodium acetate, mix thoroughly by shaking and mix for 2 min using a Vortex mixer.

⬇

Centrifuge the tubes at 10,000 rpm for 10 min.

⬇

Place 4 mL of the upper acetonitrile extract in a 15-mL polypropylene tube containing 50 mg primary secondary amine (PSA) sorbent and 150 mg anhydrous magnesium sulphate per mL of extract.

⬇

Shake the tubes vigorously and mix for 1 min using a Vortex mixer.

⬇

Centrifuge at 10,000 rpm for 10 min.

Draw 2 mL acetonitrile extract and pass through 0.2 μm PTFE membrane filters.

Analyze by GC, GC-MS, and LC-MS/MS.

Instruments used for pesticide residue analysis

Author

Dr. M.R. Dinesh